Micro dairy starts & succeeds with 5 cows!

Holy (and hardy) cows!

How 5 brown cows help micro dairy reach success

by Barbara Berst Adams

Copyright National Lilac Publishing, LLC A version of this article was first published in AcresUSA.

On

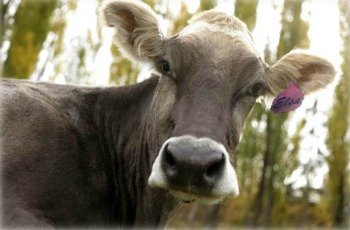

a rocky hillside in the rugged Cache Valley of northern Utah, five

Swiss Brown cows graze about 5.5 acres (4 owned, 1 ½ leased). The

really interesting part of this lovely vision is that their milk

provides the full time living for the owners of Rockhill Creamery,

Jennifer Hines and Pete Schropp, a husband and wife team who turn the

milk into artisan cheese.

How they do it

How?

Well, there’s an old truth in Northern Europe among

traditional dairy farmers. They say you can tell which meadow the milk

and cheese came from, because the flavor is different depending on the

herbs grown in the different fields. This ability to taste and

to desire the differences in different locations hasn’t died completely,

and it may be returning to the USA (and hopefully the world) in many

forms, including local eco-dairies.

It’s

an example of a revival of a way of sustainable farming. The deeper we

get into regenerative and local production, the more new pathways open

up to reveal a treasury of lost taste diversity, flavor and food

producing methods. They reveal just how exciting and unique the foods are

that wait to be discovered from country to country, from region to

region, and maybe even from meadow to meadow.

In

this author’s opinion, Rockhill Creamery is tapping into this revival

that’s even beyond the more obvious foodie and sustainability trends. It's reaching into the regenerative realm.

Beyond sustainability

Their cows are antibiotic-free,

rBGH-free, and eat grass and clover when it isn’t snowing. “Our pastures

are a combination of blue grass and clover,” Pete says. “We have tried

to keep them in more productive grasses, but we are surrounded by houses

with blue grass yards and blue grass is very competitive. We are able

to control weeds through mechanical means, and by rotating between cows,

heifers, smaller steer calves, and horses, we get a pretty good, even

graze.

"Sometimes, in the early spring, I do mow some of the high spots. We do harrow frequently. Since our farm is so small, our pastures are not the sole source of feed for our cows.

"They also eat locally grown premium dairy hay and a grain ration that has been customized for our small herd.” Pete and Jennifer’s supplements include alfalfa, some soy, corn and barley, and of course, minerals.

“We provide our cows with free choice minerals and salt. I offer them

one commercial block of trace minerals, one chunk of southern Utah

mineral salt (from the Redmond Salt Company -- the RealSalt™ people),

and a regular white salt block also.”

But

the story, the flavor, and the request from customers – including

chefs, gets deeper than this. Cheese from Rockhill Creamery is not just

cheese from generic sustainably raised cows. “We have a very nice

mineral package in our custom grain ration that they are fed twice daily

while in the milk parlor,” explains Pete. “We have a friend that helped

us develop our own ration ... no urea, or other animal sources of

protein. We use whole, flaked soybeans for our protein, whole, flaked

corn and barley for the energy. It costs us quite a bit more than the

standard dairy ration available at our co-op, but we have had several

chefs actually request copies of the ingredients lists for what our cows

eat, so our customers are quite involved with how we choose to feed our

cows.”

Further,

the creamery’s milk for cheese currently comes from Elsa, Ingrid,

Greta, a new gal named Chloe, plus the beloved Ruby, who came down with

pneumonia last

winter, but then made an inspiring recovery after the careful care

given by her owners combined with her own strength and will to live.

While all the cows are pampered and respected by their owners, they also

must become rugged and healthy themselves against the harsh white

northern Utah winters. Cheese from Rockhill Creamery is different than

that from other regions and other meadows. It’s from, as the owners

describe them, very hardy cows, and also of a unique breed of cow.

“Brown

Swiss produce milk with almost the perfect protein to butter fat ratio

for cheese making," says Pete. “We knew that we wanted to make whole-milk

cheeses, so that was important to us. The yield we get is quite high

because of that ratio. Brown Swiss are also the most beautiful of all

breeds (I am not biased in any way!). And they are the most docile --

very easy to be around, and very safe for the milker.”

Fans

of their cheese can enjoy the farm owners’ blog, entitled “Holy Cows,” a

high-tech form of the old farm journal non-farmers often love to read

and live vicariously through. It's a great farm promotional tool. We can read about how the cows love

playing in the snow, how Ruby, when ill, was covered with a blanket and

treated by the vet, and of her remarkable recovery. We can see how the

progress of the new aging room is coming along, and smile at Pete’s

amusing description of what happened when the bull was brought in.

And

their cheese-making is definitely artisan. It begins, of course, with

receiving very good milk from their Brown Swiss cows. They use

cow-to-can milking with a machine, but no pipeline. (Pete says they

can't be grade A with an open pail.) They use this high quality raw

milk with a variety of cultures to produce artisan cheeses that are

aged in their aging “cave.” The aging time is broken down into three

stages, offering a milder creamier cheese after the shortest duration,

and a harder cheese with deeper, complex flavors for the cheese with the

longer term aging. Cheese flavors include Farmhouse Gouda with its

hand-rubbed olive oil rind, Zwitser (which means “Swiss” in Dutch) for

which is added an extra enzyme to the Farmhouse Gouda to create a

flavorful variation, Peppercorn made with whole black peppercorns, Dark

Canyon Edam aged between two to four months and named after a favorite

canyon in Utah – a cheese which changes to Snow Canyon Edam after it

ages longer, more than four months, also named after another Utah

canyon. There's also a rich flavored Wasatch Gruyere, and their own cows-milk Desert

Red Feta rubbed with red salt minerals mined from Southern Utah.

How it all started

“We had been raising baby dairy heifers as replacements for some area dairies,” says Pete. “We had invested quite a bit of money and time into the business, and it seemed as though each time we just started to make some money and settle into a good working relationship, the dairy would close or go out of business. So we decided that we needed to come up with a business plan that gave us more control over our own destiny. Our farm is too small to be profitable, unless we added value to what we produced, so after considering many options, we decided the cheese business was the perfect fit for us. I really enjoy working with livestock, and Jennifer is a true "foodie."

Their market outlets

Pete and Jennifer sell their cheeses to various restaurants with names

including Deer Valley Resort and Garden Café, to retail foods markets

such as one named Sweet Peas Natural Market, and online in the form of

gift boxes, samplers, or wheels of cheese, from a quarter wheel to full

wheels. They have also established a cheese club membership where

customers can choose from a variety of subscription packages to have

cheese delivered on a regular basis.

In

addition, they operate a farmstand in their granary which they open on

Saturdays from 11 a.m. to 4 p.m. May through October. For other times,

they allow potential farm visitors to call ahead if they want to visit

the farm when the farmstand isn’t open. Their farmstand offers cheese

samples and they also sell other locally produced food items, such as

artisan bread from a producer named Crumb Brothers Artisan Bread.

The road to ultimate success

Pete

explains here how many other individuals and entities, from local

specialty food shop owners to the Slow Food Movement, helped make their

dairy a success. “When we first decided to get into the cheese business,

we introduced ourselves to the owner of one of Salt Lake City's best

specialty food shops - Liberty Heights Fresh. Steven Rosenberg is a

well-known supporter of local producers of all types. He showed quite an

interest. It took us two years to complete all the buildings, etc. When

we were finally licensed in January 2005 we got in touch with Steven

again, and he came to visit us that March. Ever since he has been a

great ally. He helped us get a spot at the Salt Lake Downtown Farmers

Market - a very large market that exposed us to thousands of folks. He

steered media folks our way, including a reporter for Via Magazine, the

West's AAA travel magazine with several million readers.

“That

same year we sold at the Cache Valley Gardeners Market here in our

valley. So, with the exposure that we received from the two farmers

markets, as well as the media, we were well on our way to developing a

recognized brand.

“In

2006 we added the Park City Farmers market to our outlets and began

approaching stores and restaurants - mostly in person, but some through

letters and samples shipped. That summer, the Utah chapter of Slow Food,

USA held a "farmer/chef mingle" in Salt Lake City and invited chefs

from the area's fine restaurants, hotels and ski resorts. We met several

chefs for the first time, and got to see others in a much more casual

setting than their kitchens. Then, that fall, we hosted a Slow Food Utah

event here at our farm. We had a couple of local chefs cater it, they

used almost all local produce, meat, bread, and of course, lots of

cheese. We had stations set up explaining all aspects of our operation.

We invited both the local lamb/beef producer and the vegetable provider

to educate our guests about their respective operations. The folks that

came to that dinner were all foodies, and included several culinary arts

instructors, a local TV station's food personality, and just a lot of

nice folks to get to know. Our local paper did a feature story on the

event.

“During

all this time, we also developed our web page, did underwriting on our

local public radio station, donated cheese to several charitable events

and kept going out and meeting chefs and cheese mongers in the Salt Lake

area.

“This

last June, our business was good enough that Jennifer was able to quit

her 3/4 time job and devote more time to the cheese business. In the

first few weeks of her new effort, we expanded into Portland and Seattle

area markets. We got a great customer in Denver. And continue to sell

more and more cheese in the Salt Lake area.

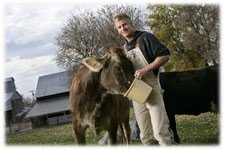

Pete

further illustrates how some marketing methods, such as their

farmstand, have proven valuable in less than obvious ways. “Our

farmstand is responsible for a very small portion of our sales - less

than 3%. But it has proven to be worth all the effort for giving us a

place to entertain visiting chefs, store staffs, etc. We have a great

customer in Pocatello, Idaho. He has a wine bar and bistro. Just before

he opened, he was out on a drive looking for local foods (Pocatello is

just 70 miles north of here) and stopped by our farmstand one Saturday.

He spent an hour seeing the operation, meeting the cows, sampling

cheese. When he left, he told us he would call in an order soon. We

thought, ‘Oh yeah, sure you will.’ The next week he placed his first

order and has been one of our greatest customers ever since.”

Plans for the future

At

the time of this writing, a new cow named Chloe had just been

purchased. Their other current milk cows are, as mentioned above, still

“Elsa, Ingrid, Greta and Ruby,” says Pete. “We have five daughters that

we are bringing along also. Iggy is Ingrid's daughter and she is due to

calve in April. We also have Heide, Greta's daughter, that will join the

herd late this summer. Opal, Ruby's daughter will also be joining the

herd this summer. And Elsie, Elsa's daughter, is just old enough to

breed right now, so she'll be in milk sometime next winter. Bell, is the

daughter of a cow we no longer have, she is a cross breed so we will

sell her when she gets a little closer to calving. She'll go to another

dairy or to a family who wants a milk cow.” Pete and Jennifer plan

to work towards becoming more profitable and less labor intensive,

while continuing to provide their great customers with fine,

hand-crafted cheese.

Advice (and a warning) for future sustainable dairy owners

“Don't

decide to milk cows, goats, sheep or anything else if you ever hope to

take a vacation again!” says Pete. “Cows must calve to come into milk.

We always dry off our cows at least two months before they are due to

calve. And, in the past, we have tried to do that all in sync

(seasonally). So far, that is not working. Our cows just don't get

pregnant the first time (that's not how my mom said those things

happened!) or anywhere close to the same time. (Plus,) seasonal milking

makes managing the rest of the business very difficult. We sell a lot of

our cheese to restaurants at very specific ages. If we were to stop

production (for all cows at the same time) all together we would have to

stop selling those cheeses for two months. We do have a few folks who

help us with milking, cleaning cheese, wrapping/packaging. Each only

works a few hours a week. So it's hard enough to find folks that can

afford to do that. If we then told them, "sorry, come back in two months

and we'll start again," it would be impossible to find help. And last

but not least, our winters are really long and can be quite miserable,

we might as well be working. I'd like to figure out how to take summers

off!”

But

the rewards are definitely there. “The first good snow of each season

gets the cows in such a playful mood,” says Pete. “They are very fun to

watch romp and play in the deep snow. The farmers market season is just

pure joy. To see the hundreds of folks that are our regular customers

come back year after year and carry on about how much they love our

cheese, that makes the long, lonely winter worth it every time. And to

be in a business that allows us to get to know the best chefs of the

area, the craziest foodies and the most down-to-earth farmers all at the

same time, now that's a business to love.” And finally, Pete reminds

current or aspiring small sustainable dairies of the following: “Stay

small and stay simple. And whatever you do, keep it fun.”Update:

Since this article was published, Rockhill Creamery is now teaming up

with Cache Meadow Creamery. It's ten miles away with nine cows -- all

with names, of course. Some of their cows came from Rockhill Creamery,

and Rockhill retired their remaining older cows to pasture and now

focuses only on cheese-making from Cache Meadow milk.

RESOURCES:

Brown Swiss Cattle Breeders’ Association’s website:

www.brownswissusa.com

You may also enjoy:

How to promote your micro eco-farm for as little as $6.00 (or less!)

__________________________